How to soundproof a shipping container

Shipping containers as music studios

Shipping containers can be used in a variety of innovative ways, from restaurants, workspaces, homes, portable toilets and even schools. You may have seen the shipping container house revisited in a recent episode of Grand Designs, which first aired in 2014 and featured within

The Mail Online. Subsequently, this famous shipping container home also made made the shortlist as one of Kevin McClouds all time favourite builds

. Here at The Soundproofing Store we are receiving more and more enquiries on how to soundproof a shipping container for use as a recording studio, or music rehearsal room.

Are Soundproof containers a good idea?

It may seem like a good idea and investment, as shipping containers are easily purchased for a relatively small amount of money and provide a watertight structure. However due to the high levels of noise and sound vibrations created by live levels of music the question is c

an thin metal panels block this level of noise effectively.Unfortunately, no. Simply put, shipping containers are not soundproof. You have to consider that the starting point of a sea container which is very poor in terms of soundproofing. It is made of a very thin layer of light corrugated sheet metal which has very little mass for blocking noise and will resonate (vibrate) allowing sound to pass through very easily.

If you stand inside a cargo container when it rains it is very loud as when the rain hits the container it causes the metal to vibrate and resonate. This sound then bounces around the inside of the container and amplifies.

So not only are we looking at soundproofing the inside of the freight container to contain the sound produced by musical instruments, but we are also needing to stop outside noise from travelling into the recording space. Do you want to spend hours on a recording to hear the noise of rain drops in the background of the recording?

In an ideal world we would advise our customers to go for a solid high-density brick structure with a heavy, dense block and beam ceiling as a starting point. Then add the separated internal walls and soundproofing which will give your recording studio a better overall result. To read more about soundproofing a recording studio in this way

click here.

However, an advantage of a container studio and building your music space inside a shipping container is that it can be moved and creates a cool environment for artists to record and practice in.

A standard shipping container is 2.43 meters wide and 2.59 meters high and available in a variety of different lengths (usually 6.10 meters or 12.2 meters). Internal dimensions though are 2.34 meters wide and 2.39 meters high due to the corrugated nature of the side walls. Space is of a premium, yet we still need to add mass to this space to effectively soundproof the container.

How to block sound?

To Soundproof a structure effectively, (whether it be a building or shipping container) we need to consider some fundamental physics of how sound is blocked.

1. Airborne sound such as music, voices and live instruments, are projected into the air as a soundwaves. To effectively block airborne sound, we need to add as much mass to the surface the sound is hitting as possible. Simply put, the heavier and denser a material is the more mass that material will have. An example of this would be concrete having more mass than paper.

2. When the airborne sound hits a surface, it turns in to a vibration energy which can travel through solid, rigid surfaces very easily. Bass frequencies carry more energy than high frequencies and will therefore create more vibration energy when hitting a surface. To soundproof effectively and stop this energy from travelling out of our shipping container we need to absorb the energy and decouple the surface (internal wall) from the external wall. (In this instance, a thin metal sea container). This is known as creating a “Room within a room.”

3. Finally, we need to address the fact that sound is omnidirectional and will travel in all directions. This means we need to soundproof the walls, ceiling and floor as well as addressing any weak points such as windows, doors and air vents. We recommend you think about your soundproofing situation a little bit like waterproofing.

How to soundproof a shipping container for louder live music levels?

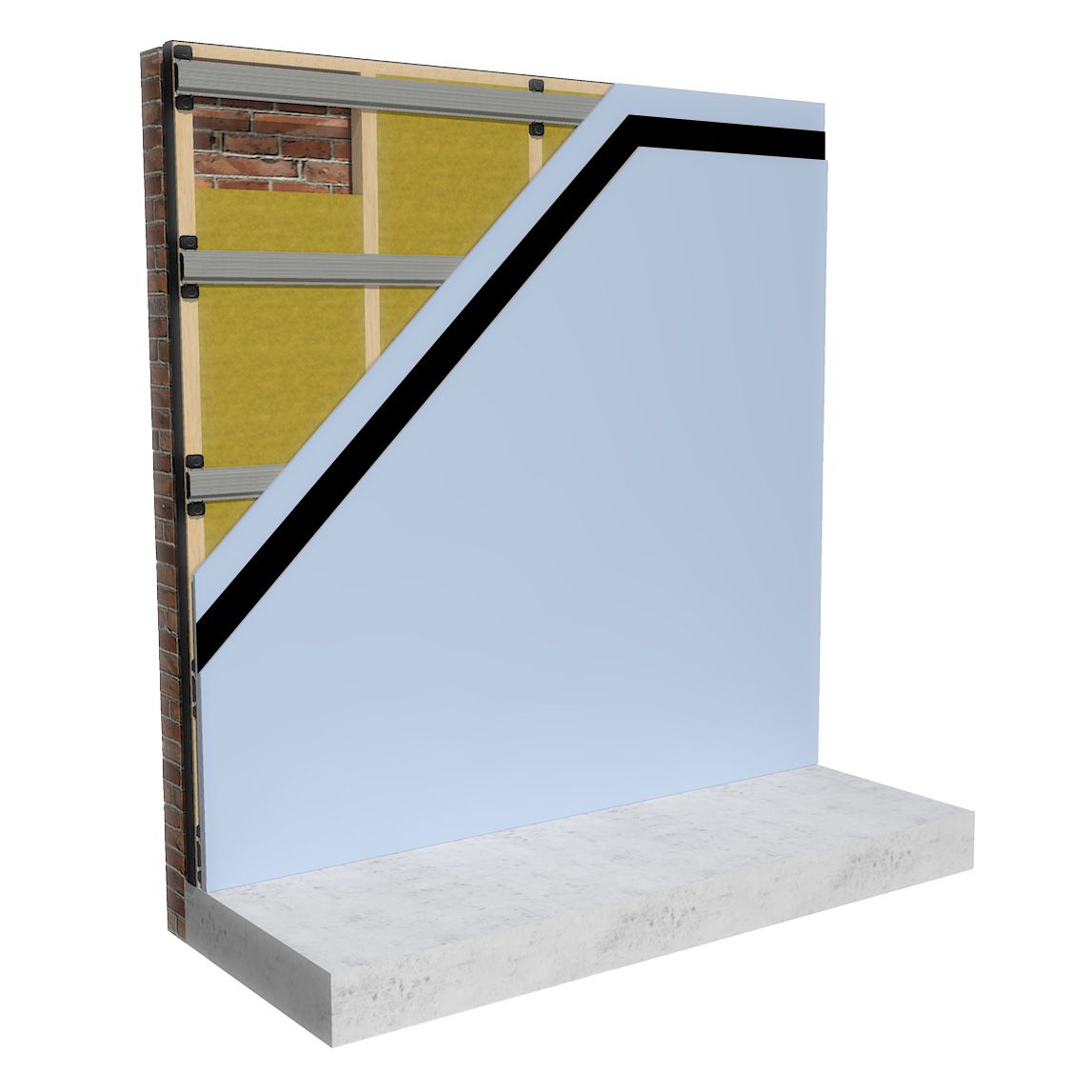

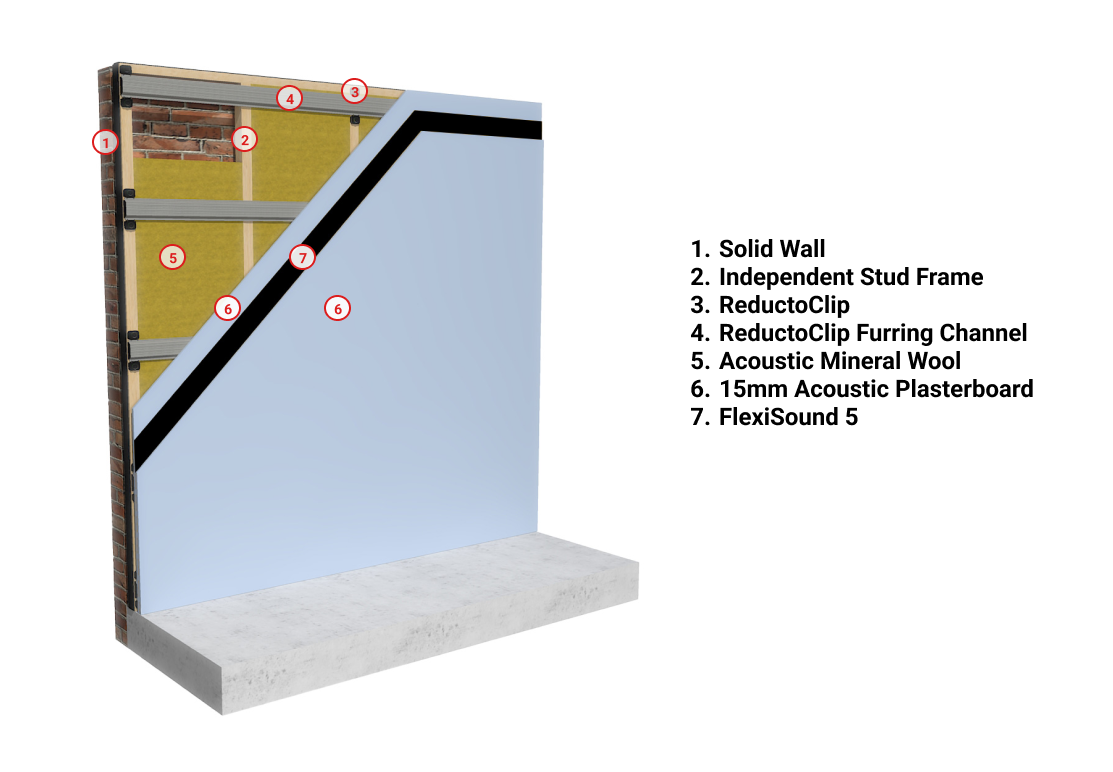

The soundproofing store’s

ReductoClip wall

and

ReductoClip ceiling system is our tried and tested solution in this situation as it offers the industry highest performing soundproofing, designed to reduce sound vibration and transmission through a surface.

As standard we build this system to take up 120mm of space per surface by using a 50mm isolated stud frame set 10mm off the original wall. Given that an ISO container has such a thin wall to begin with we would suggest, (if space allows) going with a thicker 100mm isolated timber frame to add more mass and a thicker layer of the

acoustic mineral wool to help absorb as much sound energy as possible.

To minimize the amount of contact between the stud frames and the container we isolate the frames around the perimeter with a

5mm isolation strip.

The isolation strip is designed to separate the frame and decouple it from all surfaces, whilst absorbing sound energy. This prevents sound energy from travelling through the frame and getting into the external structure. Using the isolation strip means the only solid contact point between the internal surfaces and the shipping container are the screws holding the frames in place. The amount of vibration that can travel through the screws is minimal (basically negligent).

ReductoClip™ Soundproofing Solution for Walls and Ceilings - Overview

How to soundproof a ceiling in a shipping container?

When it comes to the ceiling it gets a bit tricky as there are no existing ceiling joists to use and the ceiling is doubled up as the roof of the container.

For the ceilings we need to add timber batons/joists to be able to fix the ReductoClips to and to support the weight of the soundproofing. 50mm timber would be a minimum thickness.

We also need to make sure that where the fixings go through the container roof they are sealed and weatherproofed. You can get self-drilling screws that have a nylon washer fitted to them so that when you drill through the container this washer seals the screw head against the container and helps to prevent water from leaking through the hole you have just created.

Creating a floating ceiling within a shipping container

The alternative option is to make the joists sit on top of the stud frame walls for support and re-enforce them with noggins to make a floating ceiling. This needs to be very sturdy to support the weight of the ReductoClip system and also has the advantage of not being fixed into the roof of the container, so therefore you won’t have any issues with weatherproofing the fixings.

We would also advise applying

isolation strip along the top of the ceiling joist to prevent any flanking noise from transferring from the joist to the roof of the container.

If budget allows, we would also recommend fixing a layer of

FlexiSound 5 to the roof and walls of the container first. The thin sheet metal of the roof will vibrate a lot when it rains, creating a lot of impact vibration noise inside the studio. By fitting the FlexiSound to the inside of the container first this will reduce the ability of the metal to resonate and stop it from vibrating when it rains.

"If you have ever been inside an industrial warehouse when it rains, then you will understand how loud this can be"

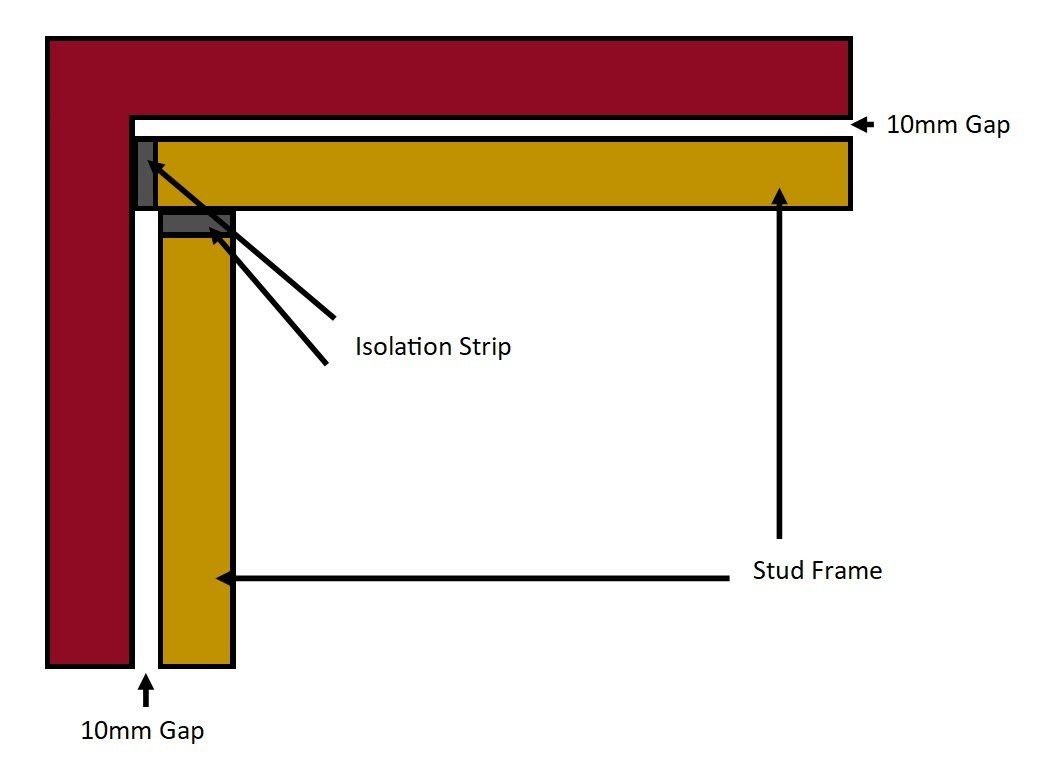

How to soundproof corners?

Corners are often asked about at The Soundproofing Store when we are looking at studio builds and are the most complicated part in the stud frame build. This is because one frame is meeting another frame on the adjoining wall and we need to do this without creating any flanking issues.

For an ISO container build we would look at using the corner design that gives the strongest support due to the frame needing to also support the ceiling joists. This involves using a single baton with isolation strip on two sides of it and fixing this to both container walls that meet in the corner of the container. You then have a baton to fix your stud frames to, making sure the frame also has isolation strip around it.

How to soundproof windows and doors?

Obviously, we need to look at the walls, floor and ceiling in terms of soundproofing but weak points in studio builds are windows and doors.

Ideally if you can get away with not having any windows this will give you the best results. Alternatively, a triple glazed acoustic window can be fitted but these are very expensive. If your site cabin is fitted with a good double-glazed window already, you could look at fitting a second double glazed window on the stud frame internally. This will give you a “Double” double-glazed window system.

With regards to the door we would recommend the same solution, using heavy dense fire doors.

Check out The Soundproofing Stores blog dedicated to door soundproofing, click here.

For a container you could get rid of the doors completely or after opening the container doors you could then be presented with the first of your doors in the double door system. One thing you could do is build the double stud work a couple of meters inside the container from the container doors to allow for some storage space.

How to soundproof the floor of a shipping container?

Finally, we do need to look at the floor of the shipping container. We need to improve the floors ability to absorb vibration, as when sound hits a solid it becomes a vibration and can travel through the structure and underneath our nicely soundproofed walls.

Also, shipping container floors are often lifted up above the base of the container itself meaning sound energy can get into the space below and out. If there is a cavity below your floor, we would recommend lifting this floor first and fitting

acoustic mineral wool into the joist below.

Same as with the walls, when sound gets into this cavity it will resonate and amplify in the cavity. We would then look at fitting our

ProSound SoundMat 3 Plus to the floor. This is a 15mm thick dense mat designed to absorb vibration energy and block airborne noise. It is very high performing and perfect for tight spaces as it doubles up as a luxury underlay for carpet floor finishes.

SoundMat 3 Plus Product Overview

How to install SoundMat 3 Plus

SoundMat 3 Plus Learn More

Summary

Hopefully this has covered most questions on how to soundproof a shipping container.

As always, if you require the best advice, speak to a professional. We are happy to talk you though any problems or answer any questions. You can call us Monday to Friday, 9am - 5pm on 01423 206 208 or contact us using the form below.