How to soundproof a loft

Potential problems with noise

Does (roof/ceiling) loft insulation reduce noise?

No, usually insulation is ineffective at reducing noise. Most lofts and attics will already include Celotex or an equivalent as part of the loft insulation. Often the term 'insulation' is used to mean thermal, keeping attics and loft spaces warm in winter and cool in summer. The term acoustic insulation and soundproofing are often used when looking at ways in which to block the passage of sound. This article focuses on soundproofing a loft, rather than insulating a loft.

Learn more about acoustic insulation .

How to soundproof a loft floor

Firstly lay acoustic mineral wool within the cavity of the floor joists. Acoustic grade mineral wool is designed to offer the highest level of sound absorption in the cavity partitions of timber floor joists (and partitions of timber and metal party walls).

Acoustic mineral wool is used within loft floors for soundproofing as it effectively absorbs airborne sounds, significantly improving acoustic performance and reducing reverberation. When acoustic mineral wool is used in conjunction with other acoustic materials, it also helps to bring separating floors and walls into compliance with Part E building regulations. (Find out more about how to pass Part E building regulations ).

After laying the acoustic mineral wool, fit an 18mm - 22mm chipboard floor as a sub floor, followed by a 5mm barrier mat to the sub floor of the loft, which then provides a base for a soundproofing sound mat acoustic underlay solution. The different SoundMat solutions are highlighted below:

What is the best soundproofing material for the floor of a loft?

Once the acoustic mineral wool has been added to the timber joists, the final floor finish of choice can determine the best floor soundproofing insulation to use. If a hard final floor finish is the final finish of choice (such as vinyl, laminate, engineered wood and tiles) then the Reverso SoundMat™ is an excellent acoustic floor solution, as it doesn't (in most instances) require a further over boarding layer before the final hard floor finish. The Reverso SoundMat can also be reversed with the soft side up for soft finishes such as carpet. Without the need of any kind of underlay.

An alternative to the Reverso SoundMat would be the SoundMat 3 Plus and SoundMat 2 Plus. As with the Reverso SoundMat, SoundMats can be added by simply laying them on top of the existing floorboards. They are constructed from layers of mass loaded vinyl for blocking airborne noise and closed cell foam to absorb impact vibration. Final floor finishes (like carpet) can then be installed directly on top, as the SoundMat act like a luxury carpet underlay. If using carpet gripper rods, then carpet gripper rod risers need to be used under the carpet gripper rods.

Laminate, tile, wooden or vinyl flooring can all be installed on top of the SoundMats. However, unlike with the Reverso SoundMat, (depending on the flooring choice) an over boarding layer is required. A 6mm bonded layer of MDF is added on top of the SoundMat for vinyl and bonded carpet finishes to give the floor a stable base. A min 9mm layer of MDF for tiles, (with 12mm being the standard).

Our recommendation would be to use the Reverso SoundMat for hard finishes and the SoundMat™ 3 Plus for soft final floor finishes. Both the Reverso SoundMat and SoundMat 3 Plus block loud levels of airborne and high impact noise. They are an extremely easy DIY instal and also offer an exceptional soundproofing performance, exceeding the new Building Regulations Part E target when used as part of a system.

Soundproofing a loft floor with the Reverso SoundMat (18mm)

The Reverso SoundMat is ideal for loud levels of airborne and high impact noise, such as clear conversation, TV noise and heavy footsteps. Suitable for all final floor finishes, without the need for an over boarding layer for most hard finishes and also acts as a luxury carpet underlay for soft carpet finishes. Only 18mm thick and is an easy DIY install, without the need for adhesive.

Innovative 3 layer reversible design:

- 6mm Fibre cement board - which provides a flat, stable base for hard final floor finishes. The mass of the board is 9.7kg per m2 which allows for the blocking of airborne noise.

- 9mm closed cell acoustic foam - provides a high level of impact absorption and unlike open cell or recycled chip foam, will not absorb water, should there be any cases of water damage in the future.

- 3mm mass loaded vinyl - offers a soft finish for carpet and also has a mass of 7.5kg per m2 to block airborne noise

Soundproofing a loft floor with SoundMat 3 Plus (15mm)

The ProSound™ SoundMat™ 3 Plusis ideal for loud levels of noise from above, such as clear conversation, TV noise and heavy footsteps.

SoundMat 3 Plus uses a specially developed innovative 3 layer design, and at only 15mm thick, means it saves space within your loft and with an easy DIY install results in minimal disruption to your home.

The innovative 3 layer design features:

1. An outer layer of 3mm mass loaded vinyl (7.5kg per m2) designed to replace lead in soundproofing. The 3mm mass loaded vinyl has the same mass and soundproofing qualities as lead, but with improved sound absorbing qualities.

2. The second and middle layer is a 9mm acoustic, closed cell foam designed to dampen and absorb impact energy (such as footsteps) from transferring through the loft floor. The foam doesn't degrade over time, is water resistant and acts as a luxury carpet underlay. The SoundMat 3 Plus also delivers a higher load capacity than standard mats meaning the internal foam layer doesn't compress as easily as the foam layer in other soundproofing mats, which compromises performance ability.

3. The third and final layer is an extra 3mm layer (7.5kg per m2) of mass loaded vinyl offering further airborne noise blocking capabilities.

Soundproofing a loft floor with SoundMat 2 Plus (12mm)

Depending on the level of noise you are trying to soundproof against within a loft, the ProSound™ SoundMat 2 offers an alternative to SoundMat 3 Plus and is another extremely effective floor soundproofing solution for lofts and attics.SoundMat 2 is ideal for loud levels of airborne noise and medium levels of impact noise (such as muffled conversation, TV noise and footsteps).

SoundMat 2 is a thin floor soundproofing mat (12mm), with 2 layers of two different soundproofing technologies laminated together for easy installation.

1. The top layer uses a specially developed thin 10kg per m2 soundproofing material of mass loaded vinyl, originally developed to replace lead in soundproofing, due to the associated health risks and with improved sound absorbing capabilities.

2. The second (middle) layer is a 9mm acoustic open cell foam designed to dampen and absorb impact energy from transferring through the base floor of the loft or attic. The 9mm soundproof foam does not degrade over time and also acts as a carpet underlay.

Floor build up using SoundMat 3 Plus and Reverso SoundMat to pass Part E building regulations

Reverso SoundMat

Reverso SoundMat

SoundMat 3 Plus

Learn MoreHow to soundproof a party wall within a loft

We have so far concentrated on soundproofing the floor within a loft or attic and now we will look at the best wall soundproofing solutions for a loft.

The most effective wall soundproofing solution for lofts depends on what the wall make up is. A solid party wall, or stud wall?

Next, what are the levels and types of noise you are trying to soundproof your loft wall against? Is it airborne noise (conversation, TV, music) or impact noise (footsteps, doors banging, scraping of furniture) or both? Also, what are the levels of noise? Muffled conversation, footsteps, up to and including excessive airborne and impact noise.

Soundproofing a loft wall

When soundproofing a loft wall, (similarly to soundproofing the floor of a loft) there are 4 main points to consider:

1. The need to improve the mass of the wall. Achieved by adding high mass/density products.

2. Improve the ability of the wall to absorb sound energy and vibration. Without this, the addition of any mass will have very little impact.

3. Add acoustic insulation between timber battens (for stud walls only) to eliminate any sound reverberation.

4. The use of different high mass materials. Different materials perform better against different sound frequencies, so using a combination of high mass materials will perform better than simply using more of the same material.

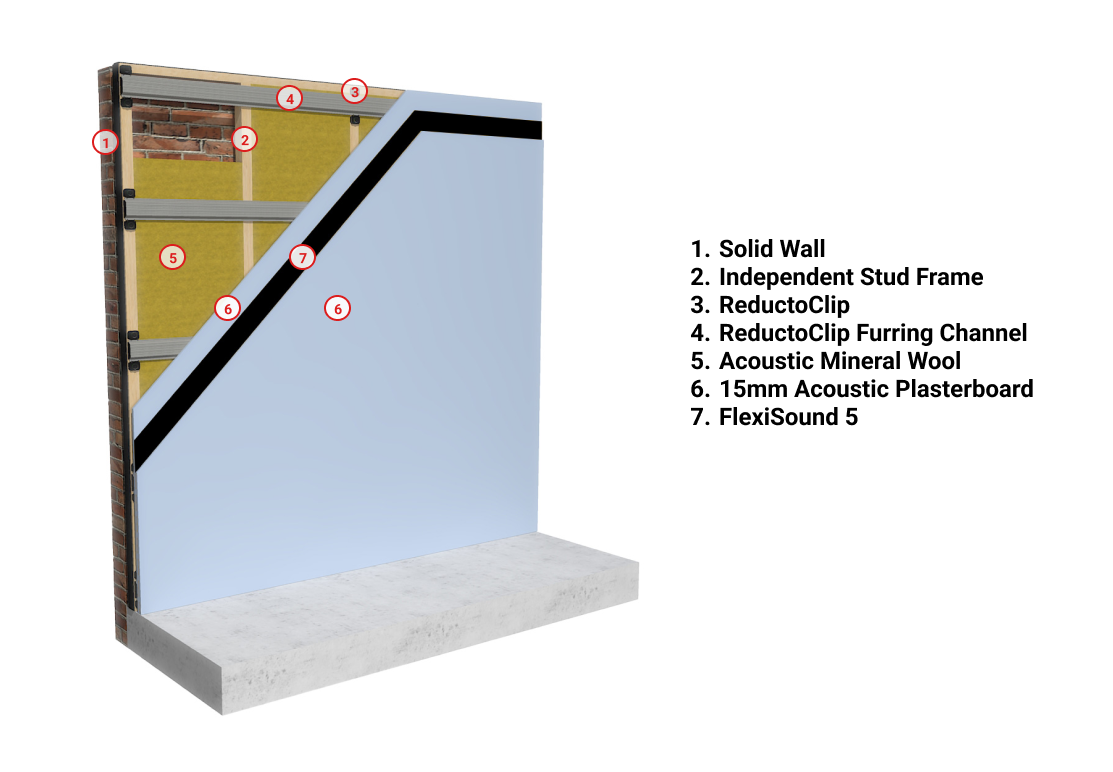

Soundproofing a loft wall with the ReductoClip Independent System

The ReductoClip Independent System is the highest performing wall soundproofing system, delivering exceptional levels of soundproofing for loft walls. This system is so exceptional at blocking noise, that it is also used for recording studios.

The ReductoClip system works by creating a room within a room, which is isolated from the existing structure meaning it absorbs high levels of sound vibration energy. The ReductoClip system is suitable for use on both solid and timber stud walls.

The ReductoClip Independent System offers an exceptional soundproofing performance for loft walls, by creating a room within a room. The system involves building a timber stud frame in front of the existing loft wall, insulating inside of the frame with acoustic mineral wool and then attaching the ReductoClips and furring channels to the frame. Finally, a new wall layer is added, with two layers of 15mm acoustic grade plasterboard sandwiching a specialist material called FlexiSound 5 .This works by adding more mass to the loft wall to block airborne noise. When the FlexiSound is bonded to the acoustic grade plasterboard its viscoelasticity properties also reduce the sound resonance / vibration of impact noise.The total build up of the ReductoClip system is 120mm.

The completed ReductoClip system works in two ways:

1. The new wall layer (plasterboard and FlexiSound) are very heavy and dense and (as previously highlighted) therefore add a great deal of mass to block airborne sound travelling through the loft wall.

2. Because these layers are fixed onto the ReductoClips and furring channels, instead of directly to the frame, this means that the new layers are completely de-coupled from the structure of the building. The ReductoClip act like shock absorbers and absorb the vibration energy, stopping any vibration from continuing into the new wall layers.

How the ReductoClip Independent Clip System Works

How to soundproof a wall with the ReductoClip Independent Wall Solution

How to soundproof a loft wall with the ReductoClip Direct to Wall Solution

It may not always be an option to lose the space of 120mm within your loft (that the ReductoClip Independent system requires). Therefore an alternative would be attach the ReductoClips Directly to the attic or loft wall (without building the stud frame) meaning space loss would only be 60mm. This method delivers an excellent sound insulation compromise on space loss v's performance.

How to soundproof a wall using the ReductoClip direct to wall solution

How to soundproof a loft wall with SoundBoard4

If the space loss of the higher performing ReductoClip wall soundproofing solutions (either 120mm, or 60mm) are still too much to lose on the attic wall, then there is another option, that of the

ProSound™ SoundBoard 4™

which is only 30mm thick.

The SoundBoard4 is a direct to existing wall system, is an easy DIY install and takes up just 30mm of space. The SoundBoard4 is ideal for blocking standard household noise, such as clear voices and TV. However, the SoundBoard 4 wouldn't be suitable for impact noise, bass sounds from music, deep voices and snoring. To block these kinds of noises, then the ReductoClip solutions mentioned above would be the only viable option.

The SoundBoard 4 delivers an airborne performance of 52dB direct to a solid wall and 54dB (for airborne noise), direct to a stud wall. In human terms it would mean a good halving of the noise. Further information on how sound is measured and decibels .

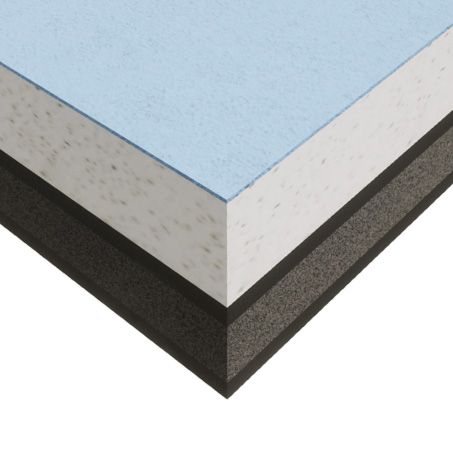

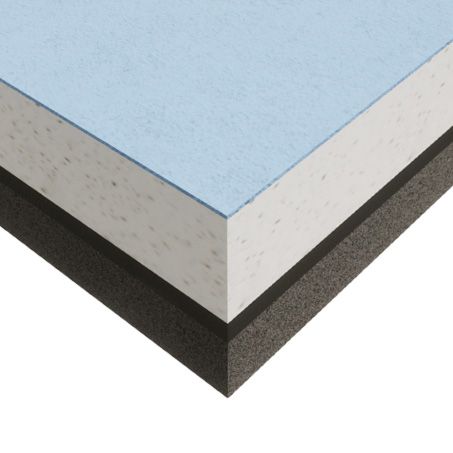

The 4 different layers that make up the SoundBoard4 work by adding different high mass soundproofing materials to block a wider range of sound frequencies and by improving the walls ability to absorb sound energy.

The 4 different layers of SoundBoard4:

1. 15mm acoustic plasterboard finish. Meaning that after installation, the SoundBoard4 is ready for a skim coat of plaster and ready to decorate.

2. 3mm mass loaded vinyl, designed to replace lead in soundproofing.

3. 9mm closed cell foam, which dampens sound energy and vibrations.

4. 3mm a further layer of mass loaded vinyl, offering greater soundproofing qualities.

Take a look at the below videos which use the same principles as those when soundproofing a solid party wall of a loft.

How to soundproof a solid wall using SoundBoard4

How to soundproof a stud wall with SoundBoard4

Soundproofing a loft wall with SoundBoard3

So far we have discussed loft wall soundproofing using the ReductoClip Independent Solution, ReductoClip Direct to Wall Solution and the SoundBoard 4. The final acoustic soundproofing solution for soundproofing a loft wall would be the ProSound™ SoundBoard 3 . The SoundBoard 3 is a solution for soundproofing loft walls against low levels of noise, such as muffled conversation, background music and TV noise and is particularly suited to the application of stud walls (more so than solid walls). At only 27mm thick the SoundBoard3 is The Soundproofing Stores thinnest direct-to-wall soundproofing board. The SoundBoard 3 features 3 layers of different high mass materials.

The 3 layers of SoundBoard3:

1. 15mm acoustic plasterboard finish, ready for standard plasterboard decoration.

2. 3mm mass loaded vinyl, designed to replace lead in soundproofing.

3. 9mm closed cell foam, dampens sound energy and vibrations.

How to soundproof the plug sockets on a loft wall

Quick tip: Soundproofing is like waterproofing and is only as good as the weakest point. For example, if you are in a car and the window is only slightly open, you can normally hear all the sound outside perfectly clearly. When you close the window fully and the car becomes more soundproofed, all sounds are reduced to a quiet muffle. This illustrates how much sound can travel through any small gaps or weaknesses.

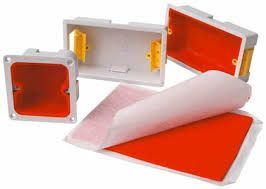

There isn't any point taking the time to soundproof a loft wall and then have gaps in the soundproofing where the plug sockets are. There are a few options in dealing with this.

Option 1. The most effective solution is to fit the SoundBoard across the whole wall and make a small hole in the soundboard and pull the cable for the socket through and then fill it with acoustic sealant . The socket would then be refitted as a surface mounted socket (so it would stick out).

Option 2: Is to fit the soundboard around the socket and fit a socket putty pad in the back of the socket.

Option 3: If the faceplate of the socket needs to fit as a regular fitting, then the back box will need to move forward 30mm by packing the wall behind the back box with a piece of wood and then remounting it. Again, a putty pad would need to be fitted at the back of this before refitting the faceplate.

How to soundproof the ceiling of a loft

Celotex will more often that not be present within your loft ceiling. This doesn't offer any soundproofing capabilities, so the loft soundproofing solutions highlighted below include the Celotex, plus the soundproofing solutions.

When soundproofing a loft or attic ceiling, due to there being no one above making impact noise (such as footsteps, or moving furniture) the noise being soundproofed against within an attic ceiling is usually airborne noise. Also, the loft ceiling isn't going to be made of concrete, it's going to be a timber joist ceiling, so this automatically means a focus on the best soundproofing solution for a timber joist ceiling to block airborne noise. Noises needing to be blocked from a loft ceiling can include voices from outside, traffic, airplanes and pigeons!

Airborne noise is only blocked by mass, (as mentioned previously) and mass comes from heavy, dense materials. Therefore to soundproof the ceiling of a loft or attic, soundproofing materials need to be added which are high mass and will improve the ability of the ceiling to block noise.

4 main points to consider when soundproofing a ceiling:

1. Adding mass and high density materials to the ceiling to block airborne noise. Using soundproofing materials such as FlexiSound and acoustic plasterboard .

2. Dampening vibrations . e.g. the noise of Airplanes through the ceiling of a loft can be a combination of both airborne noise and can also create a vibration.

3. Sound absorption , to reduce the sound echoing and amplifying in-between the timber joists. This is also known as the drum effect.

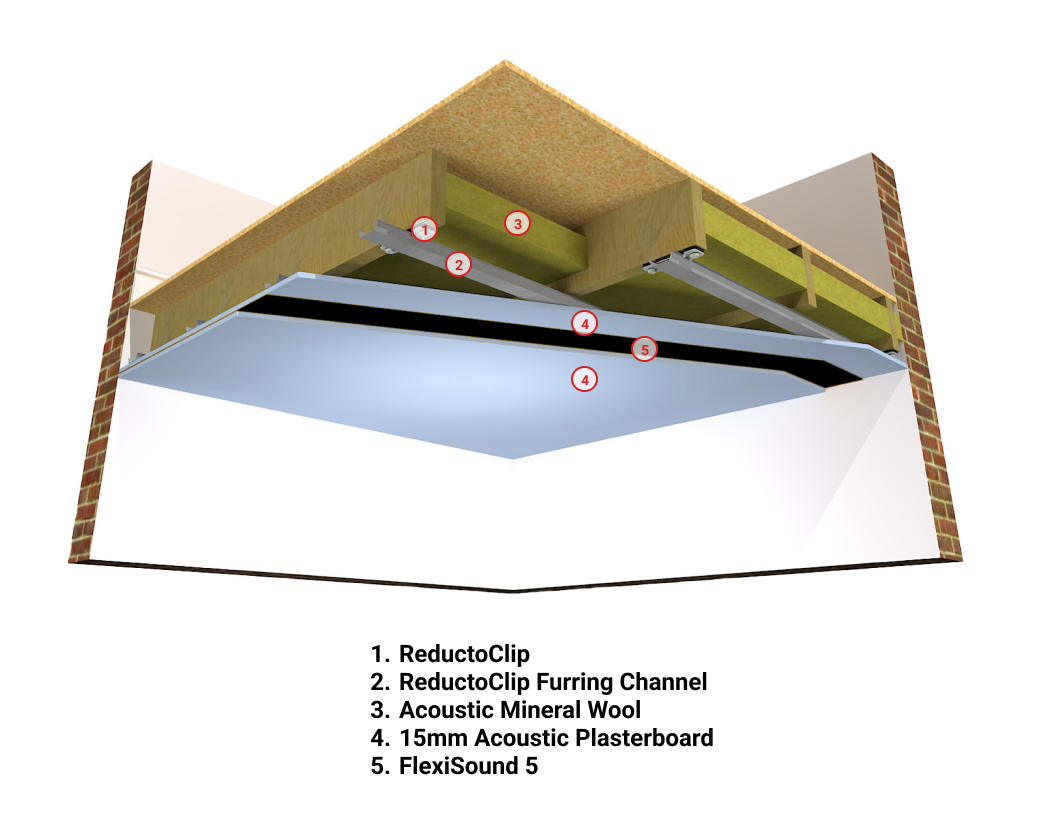

Soundproofing the ceiling of a loft with the ReductoClip ceiling system

The most effective soundproofing system for blocking high levels of noise within an attic ceiling, such as airplanes, trains, loud levels of shouting and any vibrations would be the

ReductoClip System

for ceilings . This would involve removing the current plasterboard ceiling, exposing the timber joists and adding

acoustic mineral wool into the void space.

The ReductoClips are then fixed onto the bottom of the timber joists. Long metal furring bars are then run across the ceiling fixed into the ReductoClips. The ceiling is then rebuilt, by fixing the plasterboard layers onto the furring bars instead of them being fixed directly to the timber joists. This de-couples the ceiling and any vibrations travelling down from above will be absorbed by the ReductoClips. (Like sound shock absorbers).

The ceiling is built with 2 layers of 15mm acoustic grade plasterboard, sandwiching a layer of

FlexiSound 5

in between. these layers are very high in mass and will block a high level of airborne noise. The total loss of space when using the ReductoClip system for ceilings is 60mm as there is no need to build a separate stud frame, as with the ReductoClip system for walls.

How to soundproof a ceiling with the ReductoClip System

How to soundproof the ceiling of a loft with SoundBoard 4

If there isn't the space within the attic to lose 60mm from the ceiling, then an alternative solution would be to use the SoundBoard4.

SoundBoard4 is usually used on walls to block airborne noise. Therefore, depending on the type and level of noise needing to be blocked from the loft ceiling, SoundBoard4 can be applied to the ceiling of an attic or loft. This is because, generally there will be no impact noise needing to be soundproofed against, due to no footsteps, moving furniture etc coming from above.

Firstly add acoustic mineral wool to the ceiling cavity in between the timber joists, as this significantly improves the acoustic performance by effectively absorbing airborne sound. Acoustic plasterboard then needs to be fitted and the SoundBoard4 can then be applied directly to the plasterboard on the ceiling. The SoundBoard4 is very easy to install and takes up just 30mm of space. It is ideal for medium levels of noise such as normal conversation, normal music levels and TV noise, resulting in a good halving of this noise.

The different layers that make up the soundboard work be adding mass to the ceiling of the loft and by improving its ability to absorb sound energy. The final layer is an acoustic grade plasterboard meaning after installation there is a plasterboard ready to add a skim coat of plaster to and then to decorate.

What is the best lighting to use within a soundproofed ceiling

Smart, flush spotlights inside a soundproofed loft ceiling can aesthetically look great, however they require multiple holes to be cut out. Once you have soundproofed the loft ceiling, the recommendation is to use surface mounted spotlights, or single pendant type lighting, which require just a small hole for one cable. The last thing you want to do is go to the lengths of soundproofing your ceiling and then put lots of holes in it for lighting. There should be no weaknesses in soundproofing and the addition of any holes for lighting simply creates a gap for noise to travel through.

We've mentioned it before... Soundproofing is like waterproofing. It is only as good as the weakest point.

How to soundproof the under eaves storage within a loft

Depending on whether under the eaves are used for storage, or if the space is closed off, depends on the best solution. If access is required to the eaves, then SoundBarrier mat (also referred to as mass loaded vinyl) should be applied to the floor, within the void storage area.

SoundBarrier Mat is used to combat airborne noise in floor, ceiling and wall constructions. Acoustic sealant is then applied around the perimeter to prevent any flanking vibration and seal any air gaps.

If the area under the loft is sealed with plasterboard and doesn't need to be accessed for storage, then in this instance SoundBoard4 can be fixed directly onto the plasterboard stud frame therefore blocking the noise at this point rather than on the floor in the void.

Summary

Highlighted in this article are examples of the different and most effective soundproofing solutions when soundproofing the walls, floors or ceilings within loft and attic conversions.

The main principles being that, adding mass is crucial to soundproofing. Also, using different layers of mass is more effective than more layers of the same material. Finally, ensuring the use of soundproofing solutions and materials to improve the ability of the loft (wall, ceiling, or floor) to absorb sound energy and vibration.

Share

"We don’t expect you to become an overnight expert in soundproofing, that’s what we’re here for."