How to soundproof a garden shed?

At The Soundproofing Store we speak to customers on a regular basis who are enquiring and needing advice on how to soundproof a garden shed and turn it into a music studio.

The starting point when soundproofing any space and especially important when looking to soundproof a music room or recording studio is 'what is the structure made of'?' If the structure is wood, then this can pose potential problems, the reasons as to why are highlighted below.

Why lightweight wooden structures are not good for soundproofing

There can be a big variation in 'sheds' and timber structures. A flimsy garden shed is going to be different to a more sturdy garden room or summer house. Any wooden frame with more substance and weight will always be a better starting point than a thinner, more flimsy prefabricated timber structure such as a garden shed.

Why a garden shed doesn't make a good starting point for a music studio

- Airborne noise is blocked by mass and timber structures don't have much mass, especially when compared to concrete or block structures such as garages

- They are not a strong enough structure to take the weight of soundproofing materials which are very heavy. Usually a garden shed is designed to only take the weight of itself

- To soundproof a timber structure to the same standard as a solid structure will require a 'room within a room' to be built (at least 10mm away from the existing structure). and a small shed may not have enough room to accommodate this

- A secondary ceiling is also needed and usually the ceiling height is too low to be able to do this in most garden sheds

- Most prefabricated garden sheds have flimsy doors and single glazed windows, which are not sealed or airtight. These are a serious weaknesses for noise to travel through

A garden shed does not offer a heavy or substantial enough starting point to soundproof and turn into a music studio. More sturdy wooden structures such as garden rooms can be adapted as they are often much more substantial. If you are unsure if your wooden structure (whether it be a shed, shepherds hut, summerhouse or log cabin) is a suitable structure for a music studio, then feel free to send images and dimensions (ceiling height is important) to us and we will happily advise you.

How to soundproof wooden garden room: 10 key steps

However, we have successfully soundproofed 100's of garden sheds providing that the structure is more substantial than a standard garden timber shed and there is enough head height for a secondary ceiling.

There are some key steps to follow when soundproofing a music studio within a timber structure:

- Remove any internal plasterboard or cladding

- Insulate the existing frame with acoustic insulation such as mineral wool

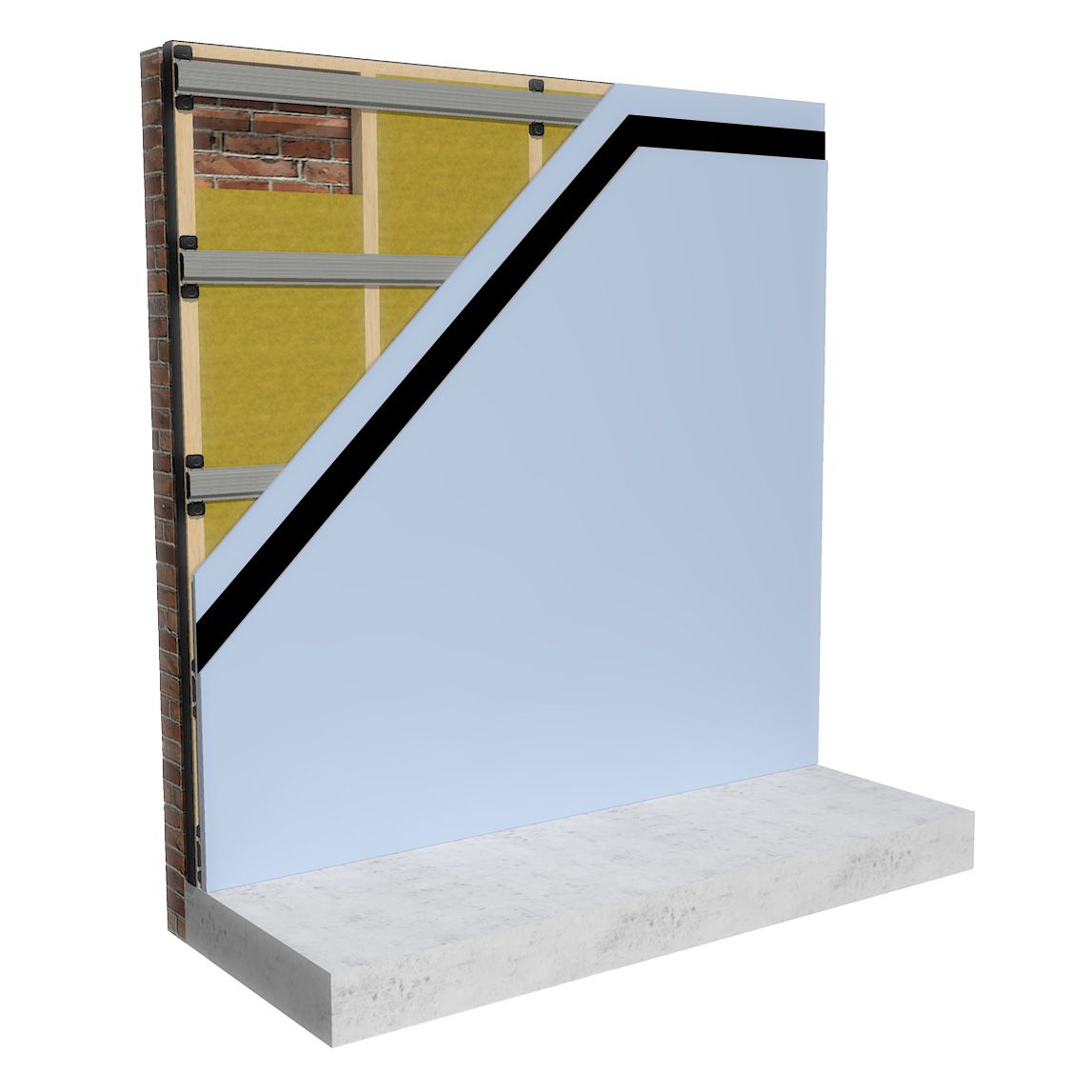

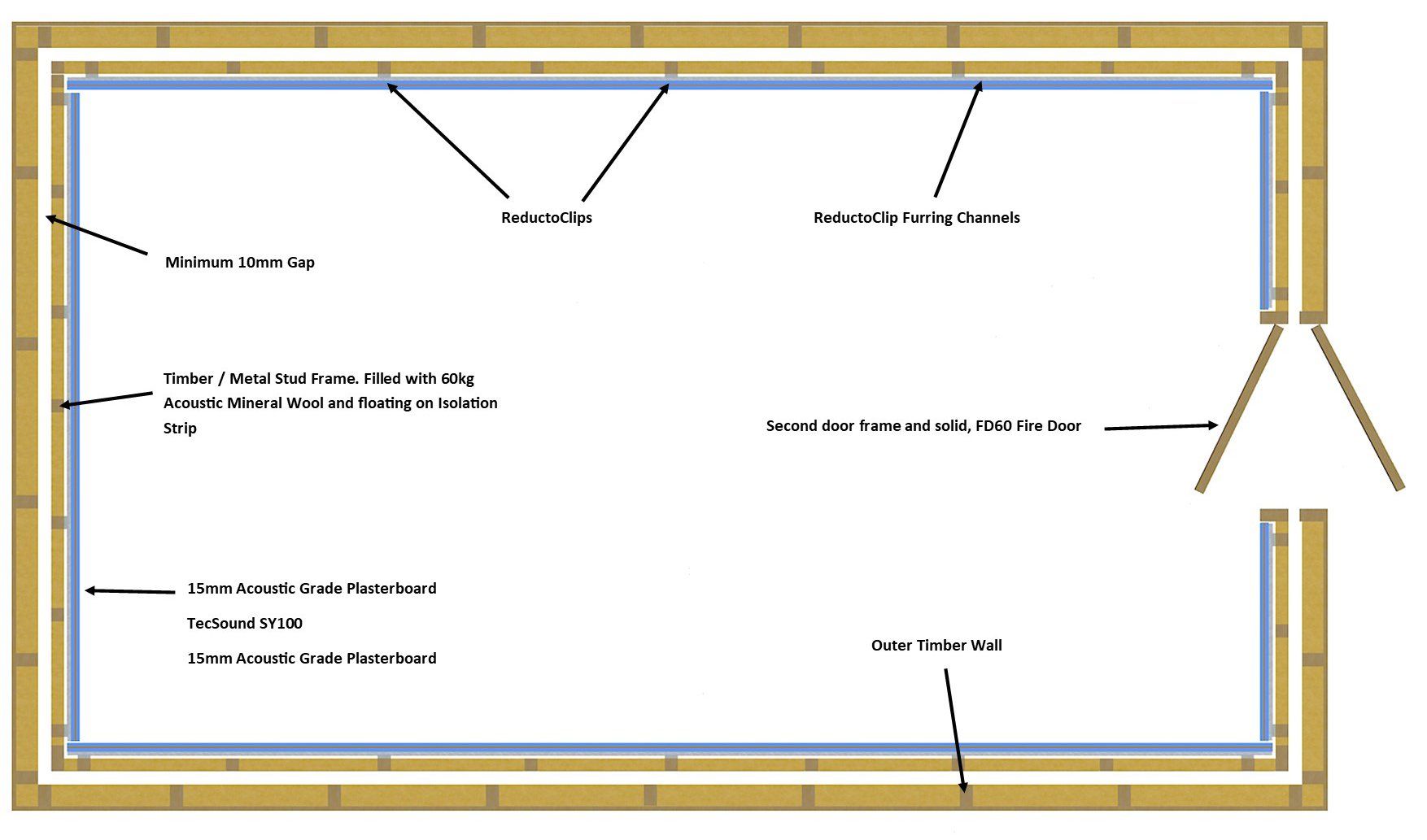

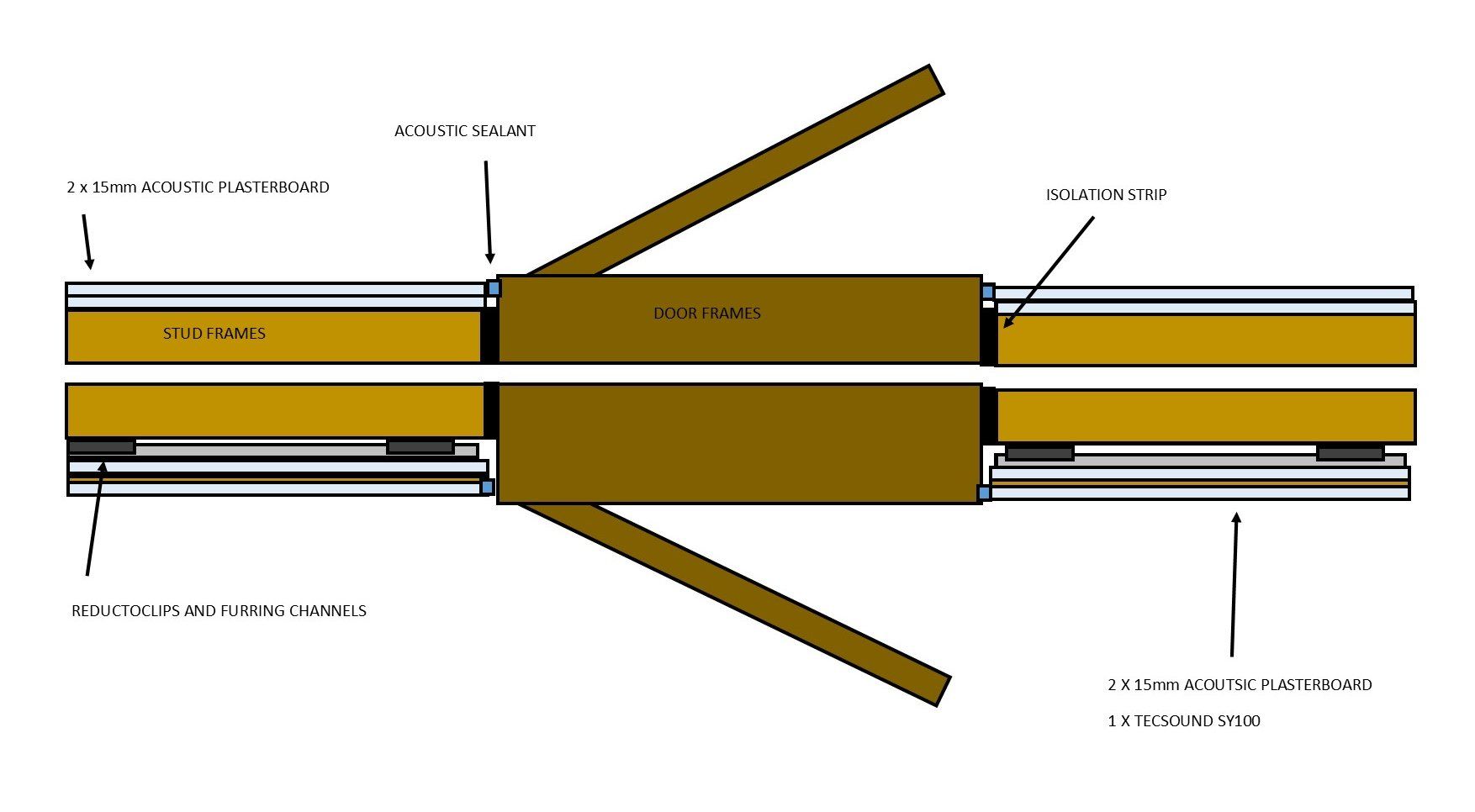

- Build a 'room within a room' (with the ReductoClip System) A stud frame is built a minimum of 10mm away from the existing structure to decouple the soundproofing layers from the original structure

- Also insulate the independent stud frame with acoustic mineral wool

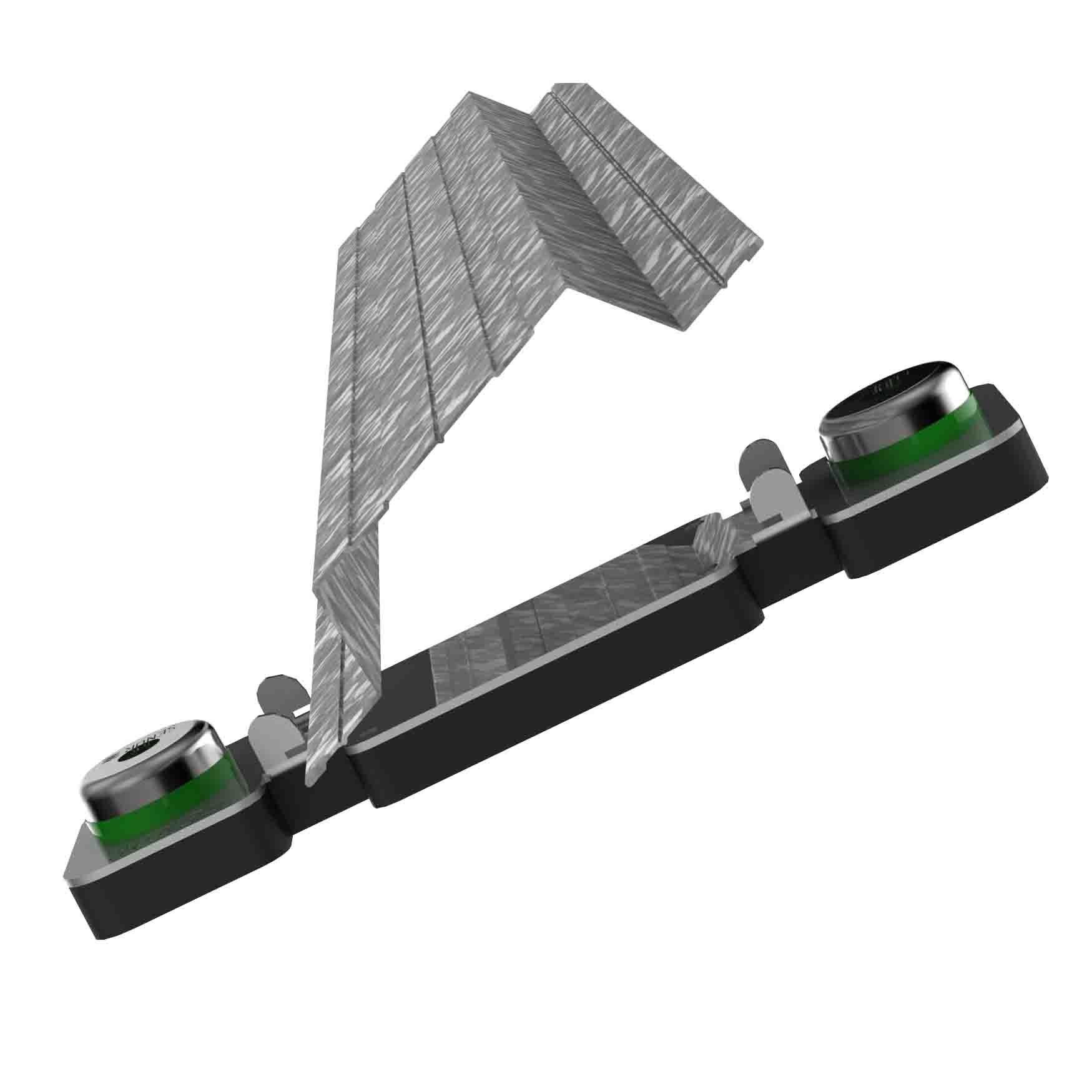

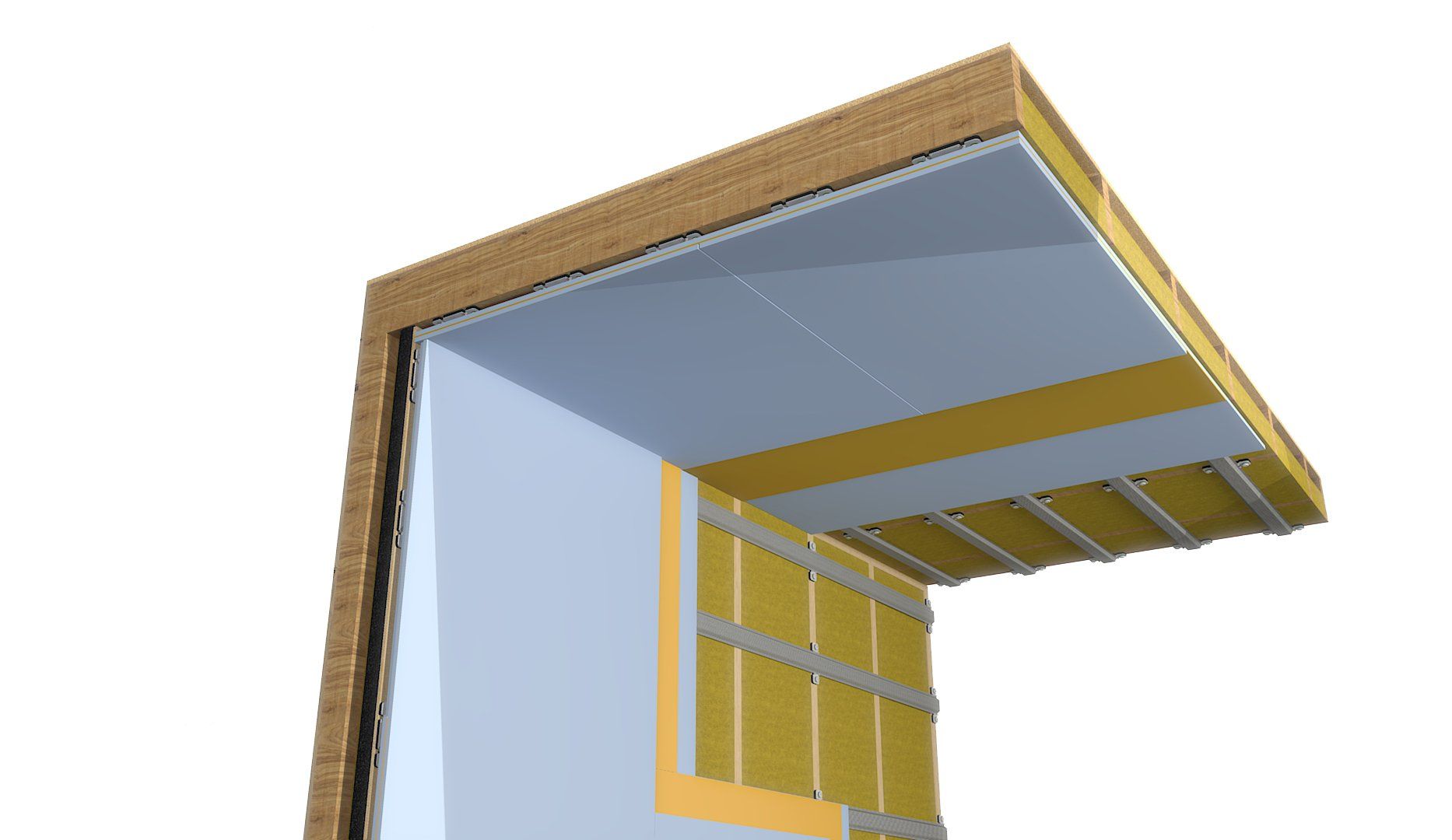

- Add isolation clips and bars such as ReductoClips and Reducto Furring bars to the new timber frame. ReductoClips are designed to absorb sound energy and vibration. They allow the soundproofing layers to flex and add resilience once the acoustic layers are added

- Add mass. Heavy and dense materials block airborne noise

- Use a combination of different heavy soundproofing materials (the law of diminishing returns if you simply use more of the same)

- Attach a recommended build up of acoustic insulation materials such as: acoustic grade plasterboard, FlexiSound and a further layer of acoustic grade plasterboard

- Upgrade windows and doors. Upgrade to heavy fire doors and install a double door system and install either acoustic triple glazing or two sets of double glazing. (even better have no windows)

- Use acoustic ventilation which is designed to ventilate and reduce the transference of noise (more details in the acoustic ventilation section below)

ReductoClip™ Independent Wall System Build-up

The importance of creating a 'room within a room' when soundproofing a music studio

For optimum results when soundproofing to the high level required for a music studio it is important to create 'a room within a room'. The new soundproof resilient walls of ReductoClips and high mass and vibration absorbing materials are built in front of the existing wooden structure, along with a suspended ceiling and floating floor above the subfloor. Basically creating a soundproof box. This stops any energy vibration from transferring through the structure of the original wooden building and spreading through the walls, floor and ceiling. This is why it's important to soundproof every surface. e.g if you only soundproof the walls the vibration will just travel through the floor and ceiling.

Add Acoustic Mineral Wool Between Joists and Voids

Acoustic mineral doesn't block sound, it is used to absorb sound within the cavities of the timber studio structure. The recommendation would be to remove any existing plasterboard or cladding within the timber structure and fill the exposed frame with acoustic mineral wool. This absorbs any sound within this void from amplifying and resonating within the space.

Acoustic mineral wool is also added between the independent stud frame, ceiling joists and floor joists. More details on each of these can be found below.

What is the preferred soundproofing system for a garden shed

As highlighted, it isn't possible to soundproof a flimsy garden shed and turn it into a music or recording studio. However, if the shed or wooden structure is more substantial the recommended solution would be to use the ReductoClip Independent System.

Why use the ReductoClip System to soundproof a music studio?

The ReductoClip soundproofing solution is an exceptionally high performing system which can be used on the walls and ceilings to soundproof a music studio.

Whilst delivering an outstanding performance against excessive noise, there are many benefits to the ReductoClip acoustic solution over and above other clip and bar systems:

- Slimmest isolation clip system on the market at only 25mm thick - almost half the thickness of other clip and bar systems

- A more substantial and robust clip compared to other clips to take the weight of heavy soundproofing materials

- Dual rubber isolation which means the ReductClip can absorb different sound frequencies compared to other clips which have only one type of rubber

- Wider spacings for the furring bars at 50mm wide mean a much wider fixing plate than alternative furring bars used with other clips. This makes installation much easier and much quicker, as there is more surface area to work with

- Furring bars have a central middle groove which makes finding the midpoint when butting up acoustic plasterboard much easier

- High density foam on the back of the ReductoClips which separates the clip from the timber frame allows flex to further absorb sound energy and vibrations. (Very similar to the way the suspension in a car absorbs the impact of a rough road and potholes).

Benefits of the ReductoClip compared to other isolation clip systems

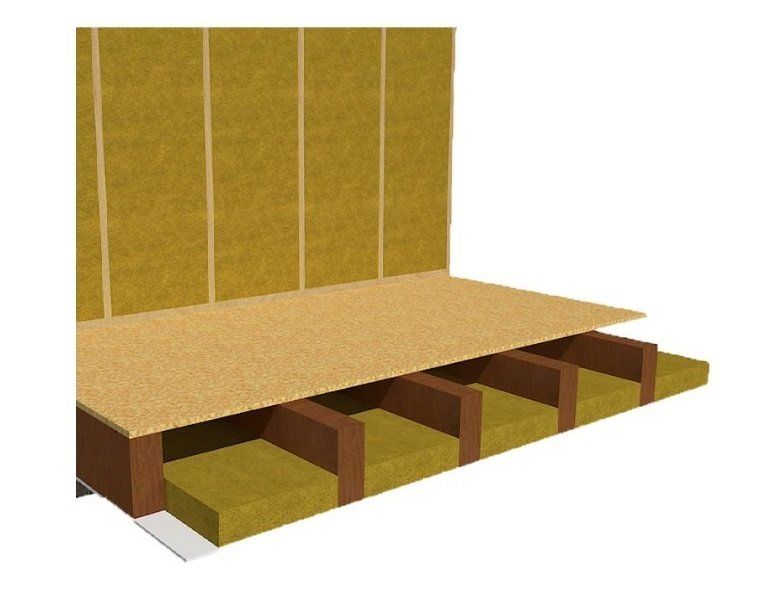

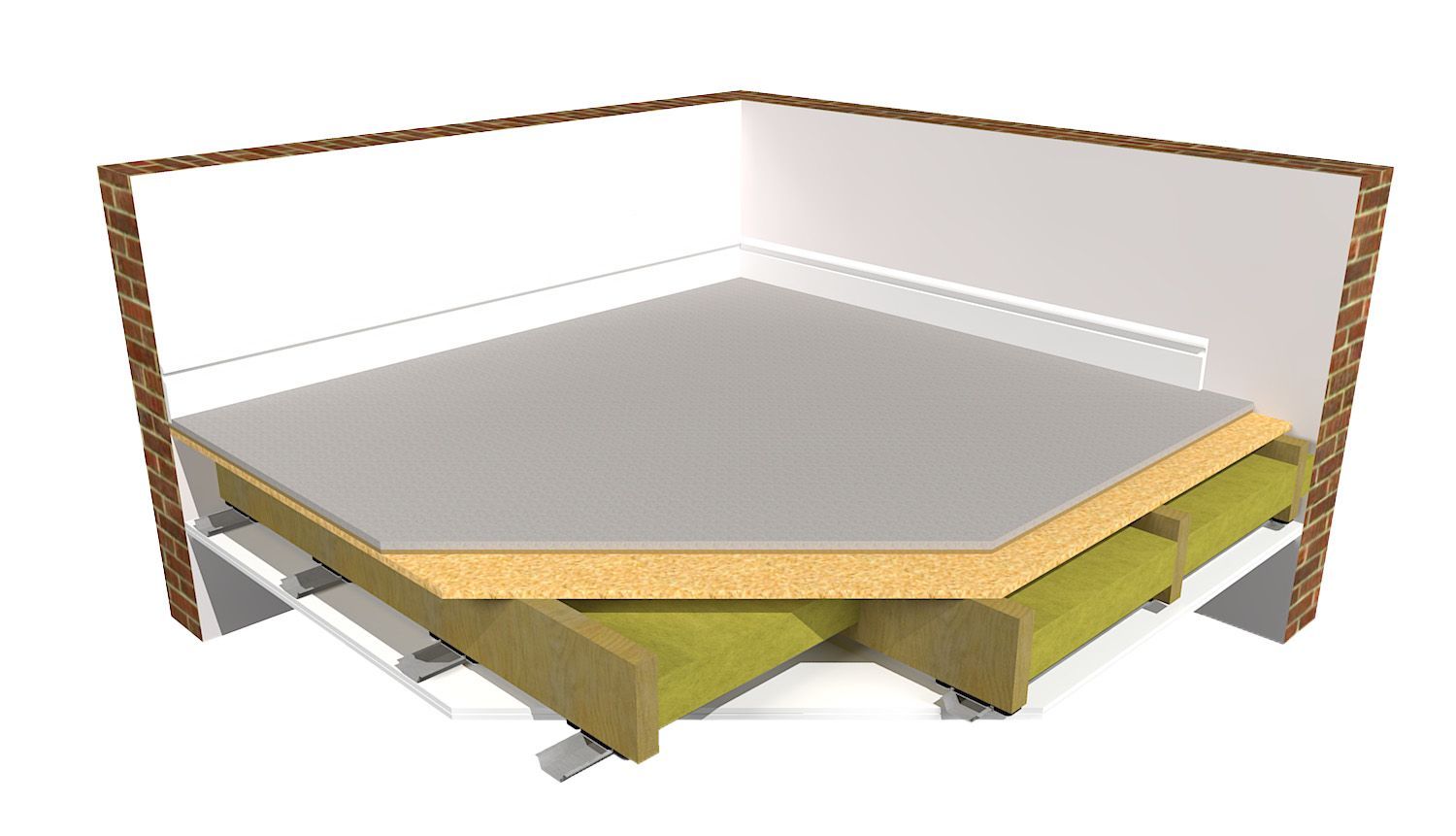

How to soundproof the floor of a timber structure

With concrete floors there is the added benefit of them already having a great deal of mass. The Soundproofing Store have a number of floor solutions which also include thin acoustic solutions to minimise any floor height buildup. However, if the floor is timber then it's a little more complex as the wooden floor doesn't provide the same level of 'natural' soundproofing qualities as that of a heavier floor such as concrete.

4 ways to soundproof the timber floor of a music studio:

- Lift the existing wooden floor and add acoustic mineral wool between joists

- Refit the the existing floor over the top of the insulated floor space

- Add more mass to the floor to help block airborne noise. Our recommendation would be SoundScreed WF28

- Add a further layer of soundproofing on top of the SoundScreed WF28 to add more mass and to also add resilience to help with impact vibrations. Our recommendation would be to add SoundMat 3 Plus or SoundMat 2 Plus

Floor soundproofing solutions for a timber floor within a music studio

Firstly remove the existing wooden floor and add acoustic mineral wool between the joists. Acoustic mineral wool isn't a soundproofing material, but is important to use as it stops any sound reverberating and amplifying within what will effectively become a mini sealed chamber.

Once the acoustic mineral wool has been added and the original wooden floor has been relayed it is important to add a soundproofing product that will add a large amount of mass to the floor.

SoundScreed 28 is an overlay board for timber floors and is used for reducing high levels of airborne sound. This is because of the large amount of mass it adds to the original timber floor. SoundScreed WF28 adds 22kg of mass per m2. The equivalent in weight of two cases of beer per m2 (other 24 packs of cans are available!)

This addition of mass helps to create a barrier to help block loud levels of airborne noise, such as music:

- 28mm thick

- 2 layers: top layer is an 18mm dry screed panel bonded to a 10mm wood fibre layer

- Simple DIY installation

- Delivers superior sound control for airborne noise

- Cost effective - cheaper than other timber floor soundproofing solutions

Learn more about SoundScreed WF28 as a soundproofing solution for studio timber floors

Soundproofing the timber floor of a music studio

SoundScreed WF28 is a great solution for the timber floors of music studios when blocking airborne noise. However, the recommendation would be to further upgrade the performance of the timber floor by also adding SoundMat 3 Plus or SoundMat 2 Plus on top of the SoundScreed WF28.

Adding one of the SoundMats is beneficial as they add further mass for blocking airborne noise and importantly also add resilience to block impact noise and vibration.

- 15mm thick

- 3 layers of soundproofing: 3mm Mass loaded vinyl, 9mm closed cell foam and a further 3mm layer of mass loaded vinyl

- Used to block both high impact noise and loud levels of airborne noise

- Acts as a luxury carpet underlay

- Easy DIY installation

- 12mm thick

- 2 layers of soundproofing: 3mm Mass loaded vinyl and 9mm closed cell foam

- Used to block both high impact noise and medium levels of airborne noise

- Acts as a carpet underlay

- Easy DIY installation

Learn more about SoundMat 3 Plus and SoundMat 2 Plus acoustic floor insulation

How to soundproof the ceiling of a timber structure

Depending on the ceiling height within the timber structure, there are a couple of options when it comes to soundproofing the ceiling of a music studio and the main principles remain the same:

- Improve the mass of the ceiling by adding different high mass soundproofing materials such as Tecsound and Acoustic Plasterboard

- Use high impact clips and bars

ReductoClips can be added directly to the joists of the ceiling. However, this depends if the existing timber joists are strong enough to take the weight of the soundproofing which is then added to the ReductoClips and Reducto Furring Channels (similar to the walls solution described at the start).

Secondary ceiling joists when soundproofing the ceiling of a timber music studio

- Acoustic mineral wool is added between the original ceiling joists

- Secondary jousts are added with an air gap below the existing timber joists. The secondary joists are attached to the top of the timber frame used in the independent wall solution. (The room within a room)

- Acoustic mineral wool is also added between the secondary joists. The ReductoClips are then attached to the secondary joists

The thickness of the timber stud frame needs to be thick enough to take the weight of the secondary joists and the thickness is also determined by the size of the timber room being soundproofed.

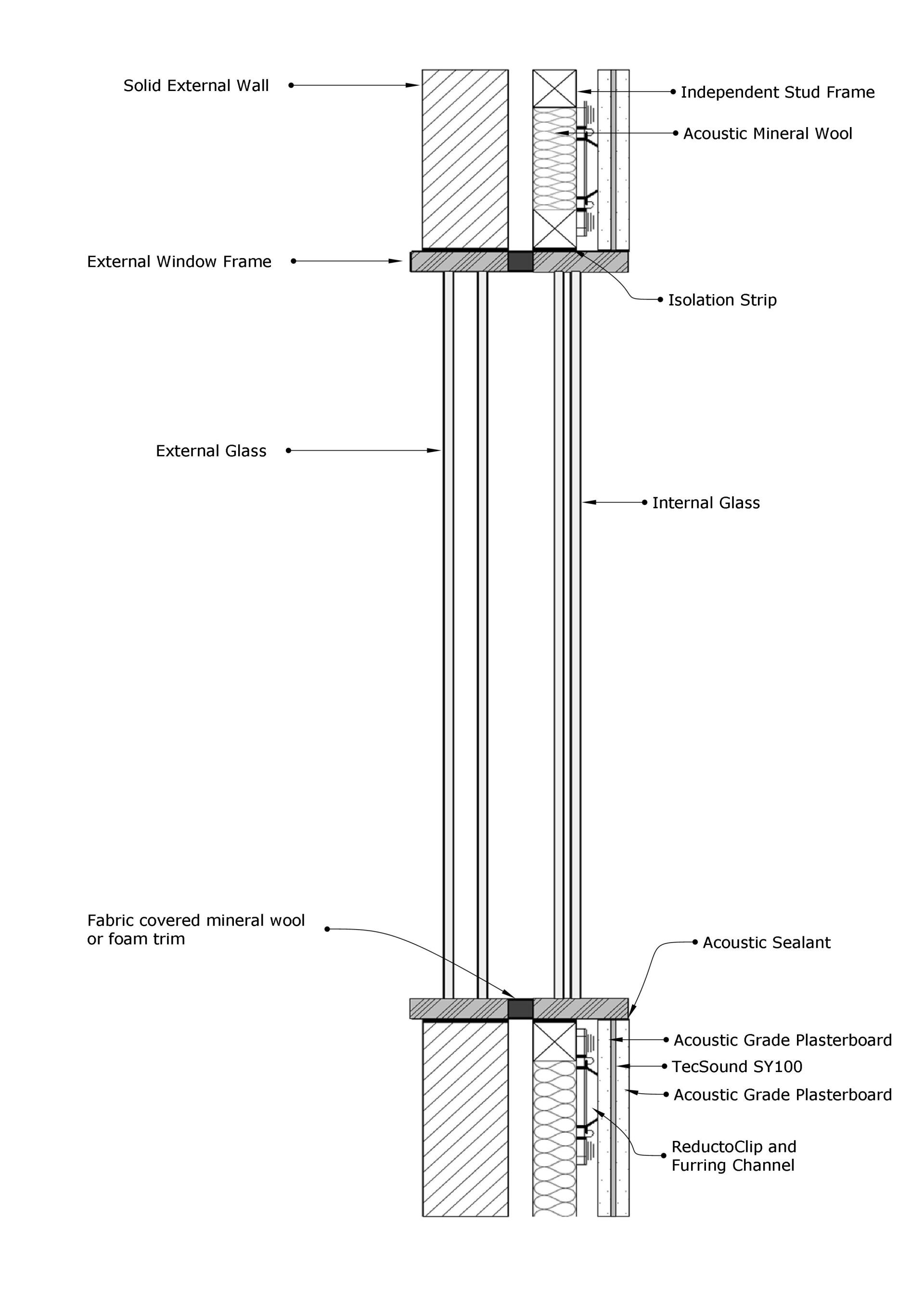

Upgrade the windows and doors of a music studio

Windows and doors will always be a weak point as they contain less mass and therefore don't naturally block noise. In a perfect world there would be just one single width door and no windows at all. However, this often isn't realistic if people want a view and/ or natural light within the studio.

If removing windows isn't an option then it is important to double them up. Because of the new soundproofed independent wall on the inside of the timber structure there will be one window on the external structure and another window (secondary glazing on the inside). This will still be a weak point, but this is the best way to minimise this weakness.

Recommended double window detail within a music studio

Single entrance doors within a music studio

The heavier and more mass a door has, the more sound it will block. As with any windows the preferred option would be to double up the door with one door on the external structure and the other door on the internal soundproof wall. Upgrading to heavier fire doors is also recommended.

Double doors when soundproofing a music studio

Acoustic ventilation comparisons for music studios

Acoustic ventilation within a music studio is tricky a it's basically the complete opposite of what is trying to be achieved when soundproofing. With the soundproofing described above the objective is to create an airtight room within a room. A barrier of sealed mass to stop air from passing in and out. When air can pass in and out, so can sound. However, when soundproofing a music studio the likelihood is that acoustic ventilation is needed. The practicalities of a musician in an airtight studio working long hours without any airflow, just isn't an option.

How to ventilate a music studio

How to achieve the best sound reduction whilst also ventilating a music studio:

- Use the best location to position the vent e.g. if possible, choose an external wall not pointing towards neighbours

- Absorb the sound by lining the vent with soft absorbent material such as acoustic mineral wool and open cell foam

- The longer the vent ducting is, with with more turns forcing the sound to bounce off the sound absorbing material, the more sound is absorbed before it leaves the vent

- Use a baffle box or sound maze which forces the air to turn multiple times and bounce off soft absorbing materials

Learn more about acoustic ventilation for music studios

ProSound™ Acoustic Vent System

The ProSound Acoustic Ventilation System 55dB is an example of an acoustic ventilation system used in music studios which provides the required ventilation, whilst also reducing the transfer of noise.

Is it possible to soundproof a shed as a music room - summary

The weaknesses of a wooden structure as a starting point of a music studio have been highlighted. If the wooden structure is more substantial than the likes of a garden shed then the key steps to soundproof a music studio within a timber structure include:

- Insulating the existing timber frame with acoustic insulation such as mineral wool

- Build a 'room within a room'. A stud frame is built a minimum of 10mm away from the existing structure to decouple the soundproofing layers from the original structure

- Add isolation clips and bars such as ReductoClips and Reducto Furring bars to the new timber frame

- Add mass. Heavy and dense materials are needed to block airborne noise

- Use a combination of different heavy soundproofing materials (the law of diminishing returns if you simply use more of the same)

- Attach a recommended build up of acoustic insulation materials such as: acoustic grade plasterboard, FlexiSound and a further layer of acoustic grade plasterboard

- Add more mass to the floor to help block airborne noise, such as SoundScreed 28

- Add a further layer of soundproofing on top of the SoundScreed 28 to add more mass and to also add resilience to help with impact vibration, such as SoundMat 3 Plus

- Add secondary ceiling joists with an air gap below the existing timber ceiling joists

- Acoustic mineral wool is also added between the original and secondary joists to stop sound from amplifying and vibrating

- ReductoClips are then attached to the secondary ceiling joists

- Upgrade windows and doors. Upgrade to heavy fire doors and double them up

- Use acoustic ventilation which is designed to ventilate and reduce the transference of noise

Should you have any questions, or need any advice on your studio build, please don't hesitate to get in touch with a member of our expert music studio team on (01423) 206208, or via the contact form below.

Share

"We don’t expect you to become an overnight expert in soundproofing, that’s what we’re here for."